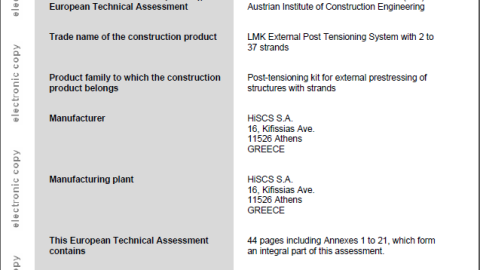

Tension rods are structural elements used in structures with predominantly static loads. Their intended use comprises for instance the suspension of constructions as well as bracing in trusses.

The tension rod system consists of steel bars (tension rods) with threads which are connected to each other and to the corresponding structure by special connecting devices (i.e., rings and forks with pins and safety nuts).

The rods are made of high strength steel (S-520) and are hot deep galvanized.

The inspection took place in several areas of the Main Terminal Building (MTB) of Athens Int’l airport, Greece.

In total 22 rods with diameter ranging from 52mm to 56mm have been inspected by HiSCS Engineer Inspector recording their length, inclination, anticorrosion protection and overall functionality.

Their loading capacity was to the range of 910KN – 1050 KN.

In some cases, readjustment of their length took place by tightening the end nuts using mechanical wrenches so as to minimize possible oscillations, thus improving their performance.

The inspector classified the service status of the rods based on the findings and proposed the recommended actions based on a priority status (long – short term).

The scope of inspection, repair, replacement, testing and monitoring of structural elements is to check that are Safe to Use, and Appropriate for the Purpose designed.

Additionally, to provide the data needed to support the management with an efficient repair and maintenance planning.