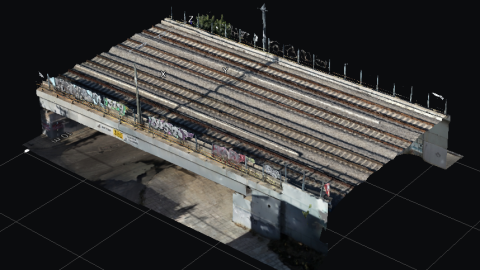

HiSCS site team has concluded the grouting works of PT tendons in the slabs-bridges of the new office complex in Maroussi area, Athens-Greece, named “THE GRID”. In total 550 flat tendons of 4 & 5 strands filled with grout following the harmonized standards EN-445-446-447.

The grouting has been performed from ground elevation up to +19.25m using a grouting pump machine with an agitator and a high-speed mixing tank capable of continuous mechanical mixing to achieve a homogeneous grout free of lumps and undispersed cement.

The grouting works commenced by blowing air inside the tendons to check the grouting penetration capability. Prior to each grout, a daily test using a cone testing apparatus was performed so as to verify the fluidity of the grout as per EN447 (Grout for prestressing tendons-basic requirements) by measuring the fluid time and temperature. Additional tests such as bleeding, volume change and grout strength were also performed.

The grout batch consisted of cement type CEM I52,5N/CEM I42,5N, expander and plasticizer admixtures and potable water not exceeding 40 lit/100Kg cement. The mixing sequence followed first water, then additives and last the cement, added gradually with precaution to be homogenized without aggregations. Mixing was of such duration, with a minimum of 2 min, to attain a uniform thoroughly blended grout without excessive temperature increase or loss of expansive properties of the admixture.

More than 7250 lit of grout were produced using +10 tons of cement and +200Kg of admixtures. Each tendon was under at min 5 bar pressure for a period of 1 min, having all its venting/grouting ports closed/sealed, was checked to assure the tightness of the tendon (no leakage). Grouting is the last in sequence of PT works and is performed as soon as possible after 24h from stressing. The process of introducing grout into the tendon is a simple and effective way to improve its overall durability by encasing the strands with a protective layer to prevent corrosion, to achieve bonding with the strand, and continuation of the structure’s section (no voids).