The Inspection and evaluation of one hundred twenty-eight (128) viscous dampers located in the Athens Metro – Line 1, in Marousi station bridge has been accomplished by HiSCS Inspectors.

Viscous dampers are considered anti-seismic hydraulic devices which through hydraulic operation (network of special oil inside internal chambers and orifices in the body of the device) can absorb (consume) kinetic energy, which is produced during the movement of the structure under dynamic actions (earthquake).

The service movements of the structure (temperature effects-contractions/expansions etc.) are taking place with zero reaction of the damper (very low velocity of damper’s piston movement).

The constitutive law of hydraulic damper is exponential, following the formula:

FD = C · Vα (MN)

Where:

C = unit constant [MN x (s/m)α],

V= the velocity of the superstructure (m/s) and

α = an appropriate exponent usually between 0.10 and 0.50.

The exponent α, if it is not specifically defined in the design stage, can be chosen by the manufacturer considering the following criteria:

– the device will not develop resistance to very slow movements of the superstructure (e.g. thermal contractions etc.)

– the device will be activated very quickly in dynamic movements.

The composition of the viscous liquid (oil) and the design details of the device are the know-how of the manufacturer.

The dampers were manufactured in 2004 having the following characteristics:

– Maximum design axial load: 75 KN

– Maximum piston movement speed: 400mm/sec

– Maximum piston extension/compression capability: ±55mm

– Exponent α ~ 0.15 KN/[m/sec] with damping constant C = 30.53

– Nominal axial length (neutral position) from pin to pin: 570mm

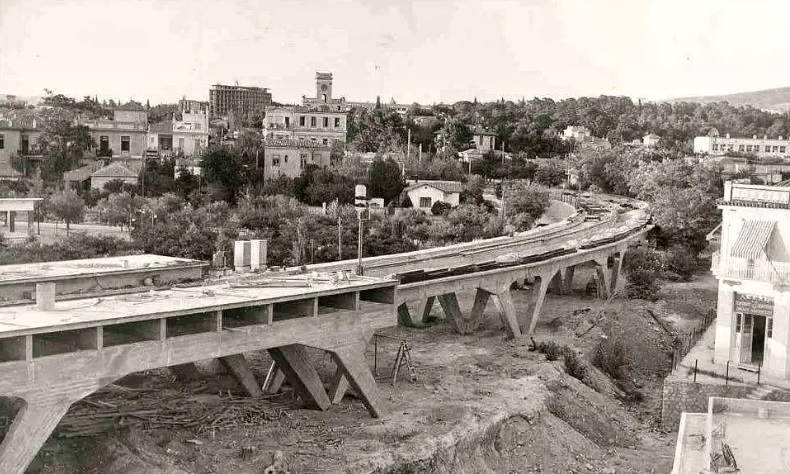

The Marousi Metro station is a concrete bridge constructed in 1955-1957 consists of 16 spans with monolithic pier-frames. The bridge serves the metro line needs as a train platform station for the passengers.

Following a regime of structurally upgrading of this old bridge, new concrete columns have been erected along its length connecting the superstructure with steel beams through the dampers, thus implementing the concept of isolating the bridge deck from ground accelerations during earthquake.

The inspection works have been accomplished by a team of 2 inspectors and 2 technicians avoiding any disturbance to the passengers and operation of the station/urban area. A movable working platform has been used to reach the dampers and perform all needed measurements and inspections.

All dampers have been checked and measurements about their function (residual movement capacity, leakage phenomena, rotation, piston condition etc.) have been recorded. A special inspection software has been used so as to speed-up the site works to a minimum possible (5 days in total, average 25-26 dampers/day).